Mainly used for processing plates, shell, molds and other high precision complex shapes of parts parts. It can finish the continuous precise processing of milling, drilling, expanding, reaming, boring and tapping on 2D/3D surface, to achieve programming machining and shorten the production cycle.

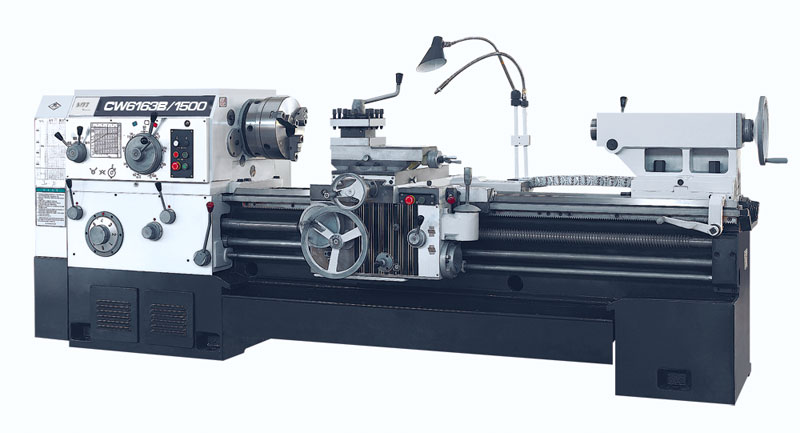

CW63/80 series as the basic model, the use of one-piece bed forms stable structure, ensures the characteristics of high rigidity. Equiped with 11kW large torque motor, combined with the optimized design of the reduced speed headstock, it can achieve high torque cutting.

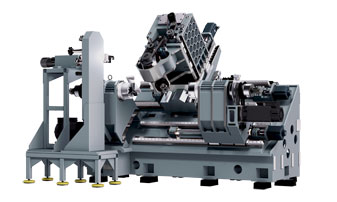

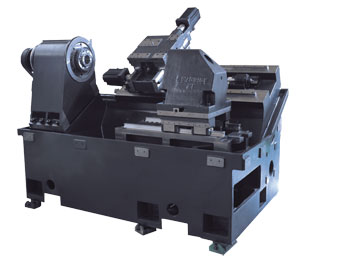

Turning milling compound machine tool perfectly combines CNC lathe and multilateral machine tool, and has the functions of CNC turning and multilateral chip forming. It can complete many

Five axis turn milling compound processing has been developed for a certain period of time

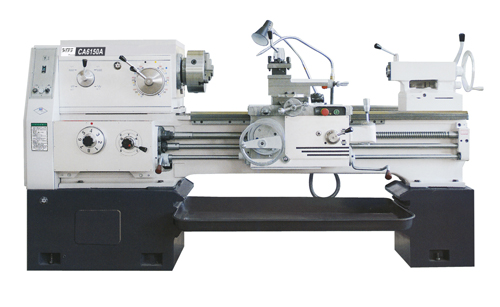

CNC machine tool is developed on the basis of ordinary machine tools

Introduction: CNC (computer numerical control) machine tool is a kind of automatic machine tool equipped with program control system

The main performance of the series has reached the international advanced level with ultra-high precision and stability. Integral inclined bed and other castings are all optimized by finite element, effectively eliminate the vibration during machine operation. Enhanced reliability, easy maintenance, high rigid structure of heavy cutting feed, so that customers can get a lasting and stable processing quality. The power turret with C axis can be installed as a turning center for more efficient and smooth processing.

For people who often meet

For you often meet

For you often meet

For you often meet

The company has more than 500 employees